Nail It Right: A Guide to Installing Hardware on Laminate Surfaces

Correctly installing hardware on laminated surfaces requires precision and careful consideration to ensure functionality and aesthetic appeal. Here's a guide on how to go about it:

Marking and Measuring:

Begin by marking the exact locations where the hardware will be installed. Use a pencil to make light marks, ensuring they are level and well-aligned. Measure and double-check the dimensions to avoid errors in positioning.

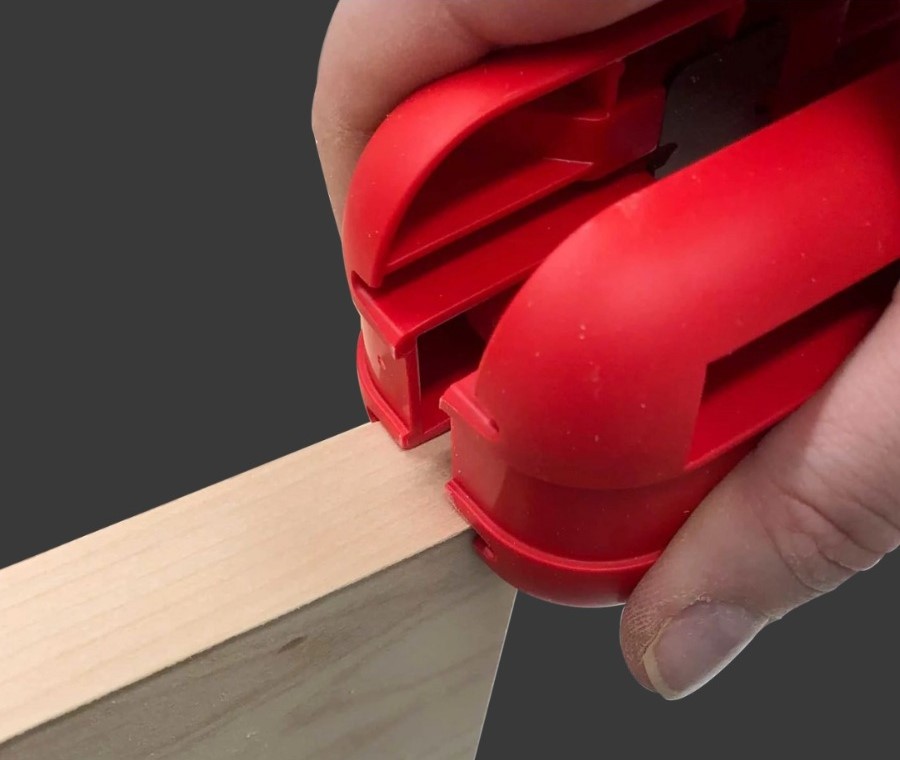

Use pre-made guides or pattern templates:

Many hardware manufacturers provide installation templates, which typically consist of plastic or paper sheets with pre-measured holes that align with the hardware's mounting points. These templates help maintain consistency across multiple installations by accurately marking hole locations, ensuring that hardware is installed evenly and consistently.

Pre-Drilling Holes:

Before attaching the hardware, pre-drill holes at the marked locations, use a drill bit that is slightly smaller than the screws to ensure a snug fit and prevent the laminate from splintering.

Selecting the Right Fasteners:

Choose appropriate fasteners based on the thickness of the laminated surface. If the laminate is applied over a substrate like MDF or particleboard, take that thickness into account when selecting screws to avoid going too deep.

Avoid Over-Tightening:

When attaching hardware, be cautious not to over-tighten screws. Over-tightening can cause the laminate to crack or chip. Use a hand screwdriver or set power tools to a low torque setting for controlled installation.

Adhesive Backplates:

For items like handles or knobs, consider those with adhesive backplates. This avoids drilling holes directly into the laminate sheet, preserving its integrity.

Seal Exposed Edges:

Seal any exposed edges if cut or drilled into the laminate to prevent moisture infiltration. Specialised Band.Edge® or sealants can be used for this purpose.

Hiding Screw Heads:

If screw heads will be visible, use matching covers or caps to conceal them. These can be colour-matched to the laminate or hardware for a cohesive look.

Professional Installation for Complex Hardware:

For complex or intricate hardware installations, especially those requiring precise alignment, consider hiring a professional with a CNC drilling machine and have the laminated panels sent to their factory. Experienced installers have the tools and skills to ensure a flawless result.

Protective Measures:

Protect the laminated surface during installation using soft cloths or cardboard to prevent scratches or damage. Work methodically to avoid accidental marks. Always refer to the manufacturer's guidelines and instructions for installing specific hardware. This ensures you adhere to any recommendations or requirements for the best results.

By following these steps and exercising care during the installation process, one can successfully install hardware on laminated surfaces, while preserving the integrity and aesthetics of the material.